A Necessary Invention

Detecting Gas at Teralba Colliery

The proverb ‘necessity is the mother of invention’ is possibly never more apt than when applied to the portable mine gas detector. Throughout mining history, countless miners have lost their lives in explosions caused by the inflammable methane gas that accumulates underground through the transformation of ancient plant material into coal.

But from the 1950s, a newly invented precision instrument came to the rescue – the interferometer. It was a revolutionary methanometer that replaced the previous sacrificial canaries and electric safety lamps that had been in use for decades. This one was used at the Teralba Colliery, in the Hunter Valley, which operated between 1978 and 2001. It was much-needed there, because the methane in Teralba’s workings was abundant, giving the mine the reputation as one of the ‘gassiest’ in the region.

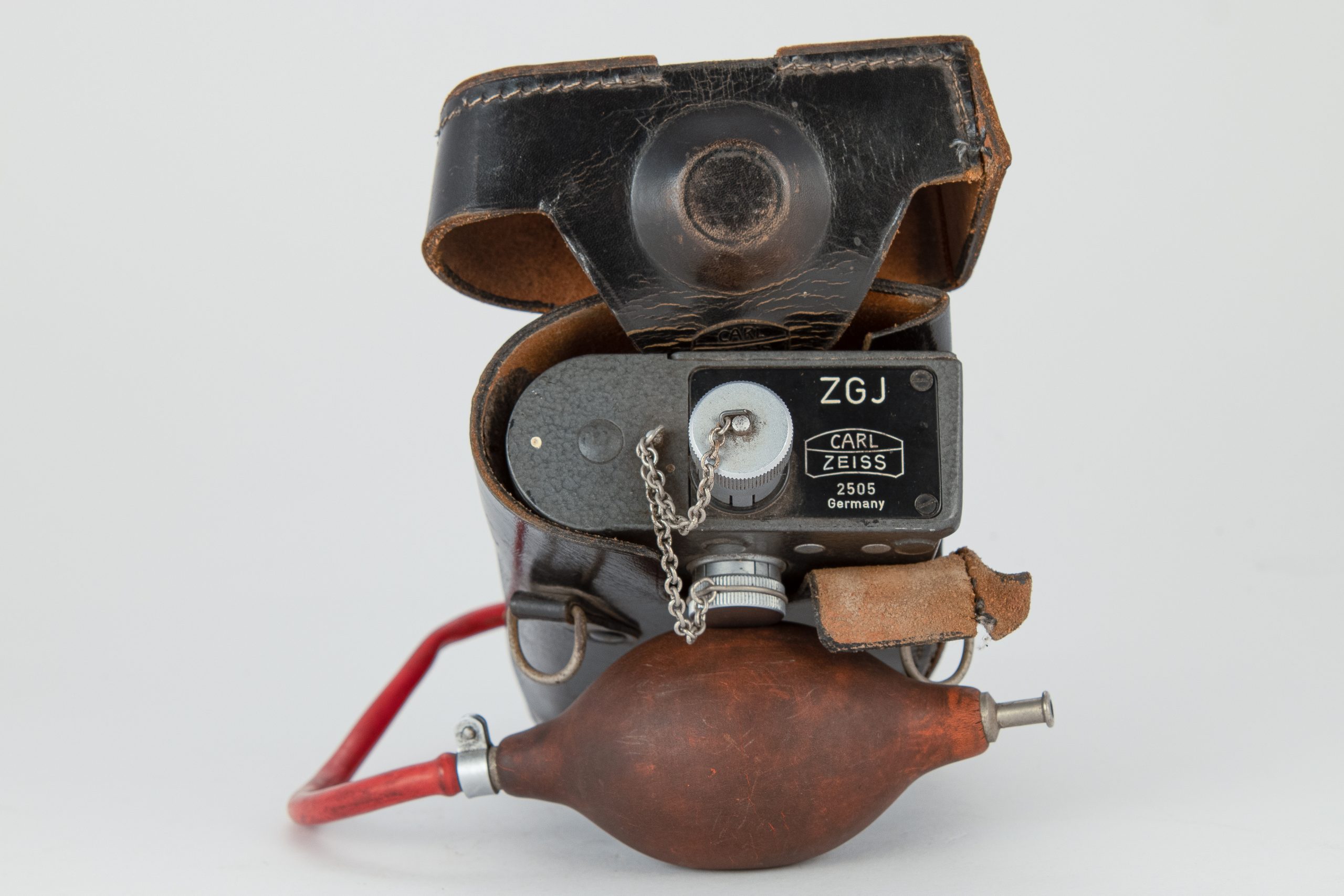

This ZGL 2505 interferometer used there, was manufactured in 1957 in Germany by precision instrument maker, Carl Zeiss. It could measure underground methane and carbon dioxide with a previously unknown level of accuracy, based on the principle of the refraction of light rays in gas. A squeeze of the rubber bulb sucks air into the device and a lamp inside divides the light that travels through the gas, resulting in an interference pattern. This is then measured and read as stripes on a scale through the eyepiece.

Of all the inventions in use in the history of coal mining, the gas detector is probably the most important. But the Zeiss Interferometer was expensive and difficult to operate in the difficult underground conditions, and other portable methanometers replaced it in the 1960s. And despite the regular use of hand-held, portable gas testers like this, gas explosions still occurred in the Hunter Valley coal mines. Today, the job is done by robotic gas detectors.